Full of dry goods: basic knowledge of pipeline pumps

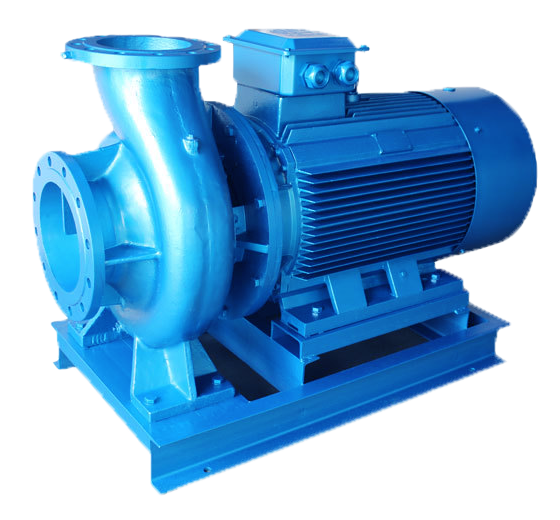

Pipeline pumps belong to the category of centrifugal pumps, as their inlet and outlet are on the same straight line and usually have the same diameter, resembling a section of pipeline. They can be installed at any position in the pipeline, hence the name.

Next, let's learn about the classification and basic structure of pipeline pumps.

1、 Classification of pipeline pumps

1. Single stage single suction pump for clean water pipeline

Used for high-rise building water supply, heating, industrial and domestic water supply and drainage, pressurization, industrial pipeline pressurization and transportation, cleaning, refrigeration and air conditioning circulation, water supply equipment and boiler accessories, the operating temperature is usually controlled below 80 degrees.

2. Pipeline single-stage single suction hot water pump

The IRG type single stage single suction hot water pipeline pump for high-temperature hot water boilers in metallurgical, chemical, paper mills, timber, restaurant, textile, bathroom, hotel and other departments, with a operating temperature generally not exceeding 120 degrees.

3. Pipeline single-stage single suction chemical pump

A pipeline pump used for conveying chemical corrosive liquids in industries such as textiles, pharmaceuticals, hygiene, food, chemical, petroleum, and refining, with a operating temperature not exceeding 100 ° C, is an ideal product to replace traditional chemical pumps.

4. Pipeline single-stage single suction pump

It is an ideal product for traditional oil pumps, suitable for transporting oil products and flammable and explosive liquids in refineries, oil depots, chemical and power departments of enterprises and institutions. The operating temperature needs to be within 120 degrees.

5. Pipeline high-temperature oil pump, pipeline high-temperature chemical pump, pipeline high-temperature hot water pump

It is a model formed on the basis of adding water cooling units, with operating temperatures up to 180 degrees or even higher.

2、 Construction of Pipeline Pump

The basic structure of a pipeline pump consists of six parts: impeller, pipeline pump body, pump shaft, bearings, sealing ring, and packing box.

According to different installation methods, it can be divided into vertical pipeline pumps and horizontal pipeline pumps.

1. Impeller

The impeller is the core part of a centrifugal pump, with high rotational speed and high output. The blades on the impeller play a major role, and the impeller needs to undergo static balance experiments before assembly. The inner and outer surfaces of the impeller are required to be smooth to reduce friction losses caused by water flow.

2. Pipeline pump body

The pipeline pump body, also known as the pump casing, is the main body of the water pump. Plays a supporting and fixing role, and is connected to the bracket for installing bearings.

3. Pump shaft

The function of the pipeline pump shaft is to connect the coupling with the electric motor, transmitting the torque of the electric motor to the impeller, so it is the main component for transmitting mechanical energy.

4. Bearings

Bearings are components that are placed on the pump shaft to support the pump shaft, and there are two types of bearings: rolling bearings and sliding bearings.

Rolling bearings should be lubricated with butter appropriately. Generally, a volume of 2/3-3/4 will generate heat if too much is used, and if too little is used, there will be noise and heat!

The sliding bearing uses transparent oil as a lubricant and is filled to the oil level line.

Too much oil will seep out and float along the pump shaft, and too little bearing will overheat and burn out, causing accidents!

During the operation of the water pump, the highest temperature of the bearings is 85 degrees Celsius, usually around 60 degrees Celsius. If it is too high, the cause should be investigated (whether there are impurities, whether the oil quality is black, whether there is water ingress) and dealt with in a timely manner!

5. Sealing ring

Sealing ring, also known as leak reducing ring. Excessive clearance between the impeller inlet and the pump casing can cause water in the high-pressure area of the pump to flow towards the low-pressure area through this clearance, affecting the pump's water output and reducing efficiency! A small gap can cause friction and wear between the impeller and pump casing.

In order to increase reflux resistance and reduce internal leakage, delay the service life of the impeller and pump casing, a sealing ring is installed at the junction of the inner edge of the pump casing and the external support of the impeller, and the sealing gap should be kept between 0.25 and 1.10mm.

6. Stuffing box

The packing box mainly consists of packing, water seal ring, packing cylinder, packing gland, and water seal pipe.

The main function of the packing box is to seal the gap between the pump casing and the pump shaft, preventing the water flow inside the pump from flowing outside and the air from outside from entering the pump. Always maintain vacuum inside the water pump!

When the friction between the pump shaft and the packing generates heat, it is necessary to rely on the water seal pipe to trap water into the water seal ring and cool the packing!

Maintain the normal operation of the water pump. Therefore, special attention should be paid to the inspection of the packing box during the operation and inspection of the water pump.